Thane, Maharashtra

- GST NO. : 27AAHFE6059N1ZV

| Business Type | Manufacturer, Exporter, Supplier |

| Watts | 10-20 W |

| Heater Type | Flexible |

| Power Source | Electric |

| Click to view more | |

Product Details

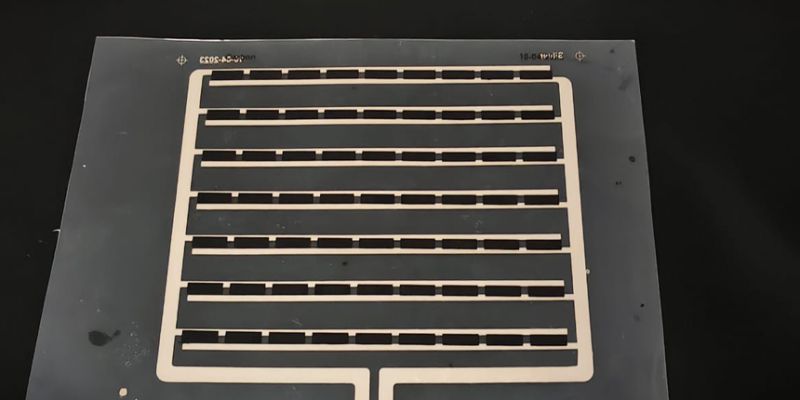

Flexible Heaters

Flexible Printed Heaters are simple warming elements that are screen printed on flexible materials. Through careful control of design elements and the deposition of functional inks, flexible printed heaters can be made to specific operating parameters and can be customized according to user requirements.

Conventional heaters are heavy to transport, take up space, and can also fail due to faulty wires or coils. Printed heaters can be a solution to all these problems. Printed heaters are used in heated garments, automotive and medical applications, etc.

Key Features of Flexible Heaters:

- Flexibility: Designed to bend and conform to complex shapes, allowing integration into diverse applications.

- Thin Profile: Typically, very thin, minimizing space requirements and enabling use in compact assemblies.

- Uniform Heating: Provide consistent heat distribution across the surface, enhancing performance.

- Customizability: Available in various shapes, sizes, and watt densities to meet specific application needs.

- Rapid Response Time: Quickly reach operating temperatures, improving process efficiency.

Common Specifications:

- Temperature Range: Operating temperatures can vary; for instance, silicone rubber heaters can operate up to 232°C (450°F) , while polyimide (Kapton) heaters typically operate up to 200°C.

- Watt Density: Standard watt densities range from 2.5 W/in² to 10 W/in², with custom options available for specific requirements.

- Thickness: Generally between 0.01 inches (0.25 mm) and 0.03 inches (0.76 mm), depending on the material and construction.

- Voltage: Available in various voltage ratings, commonly from 12V to 480V, to suit different power supply configurations.

- Sizes: Can be manufactured in sizes ranging from small dimensions (e.g., 10 mm x 10 mm) up to large areas (e.g., 2 ft x 3ft) , depending on the application.

Material Selection

- Heater Element: Typically made from materials like conductive inks that can generate heat when an electric current passes through.

- Substrate: For window heaters, a transparent material like glass with conductive elements printed or embedded in it is used. For seat heaters, flexible materials like carbon fiber are common.

- Adhesives and Insulators: For proper installation, heat-resistant adhesives and electrical insulators are required to ensure safety and durability.

Application

- Medical Devices: Maintaining patient temperatures, warming intravenous fluids, and blood analyzers.

- Aerospace: De-icing equipment, temperature control of instruments, and satellite components.

- Electronics: Preventing condensation in enclosures, battery warming, and ensuring optimal operating temperatures for components.

- Automotive: Seat heaters, mirror defoggers, and battery warming systems.

Specification

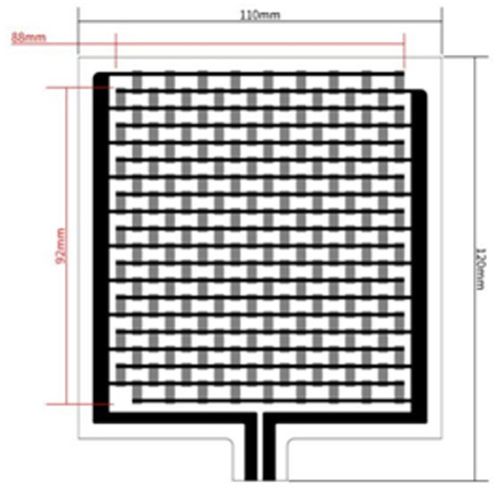

| Sl.No | Parameters | Readings |

| 01 | Length | 120mm |

| 02 | Width | 110mm |

| 03 | Activearea | 88 x 90mm |

| 04 | Pinspacing | 15mm |

| 05 | Nominalthickness | 0.2mm±0.1mm |

| 06 | Substrate | PET |

| 07 | connector | 2-pin male solder tabs |

| 08 | Thickness | 0.73mm |

| 09 | Width | 1.6m |

Looking for "Flexible Heater" ?

Explore More Products